Heavy-duty Steel Kerb

Bison

Perfect for- Service Roads

- Pavements

- Pathways

- Other building developments

Achieve an effortlessly clean edge with metal driveway edging from Kinley, the number one choice for homeowners and landscapers.

Designed to frame your driveway and create a seamless transition between the elements of your landscape. Kinley's metal edging solutions create a polished and processional appearance every time.

Explore a selection of finishes for your metal driveway edging, offering a range of options to suit every taste. Complement your outdoor aesthetic with the perfect choice for your landscape project.

Mark, cut, lay, connect. Get ready to redefine your landscape in just 4 simple steps.

Metal driveway edging is more resistant to damage than concrete kerbing and timber. It withstands harm from machinery, impact, rot, and frost.

Aluminium and galvanised steel also offer excellent corrosion resistance and will be maintenance-free for decades.

At Kinley, we have edging products for every type of driveway surface. This includes hot-rolled asphalt, tarmacadam, resin-bound gravel, rolled aggregates, poured or precast concrete, block paving, and cobblestones.

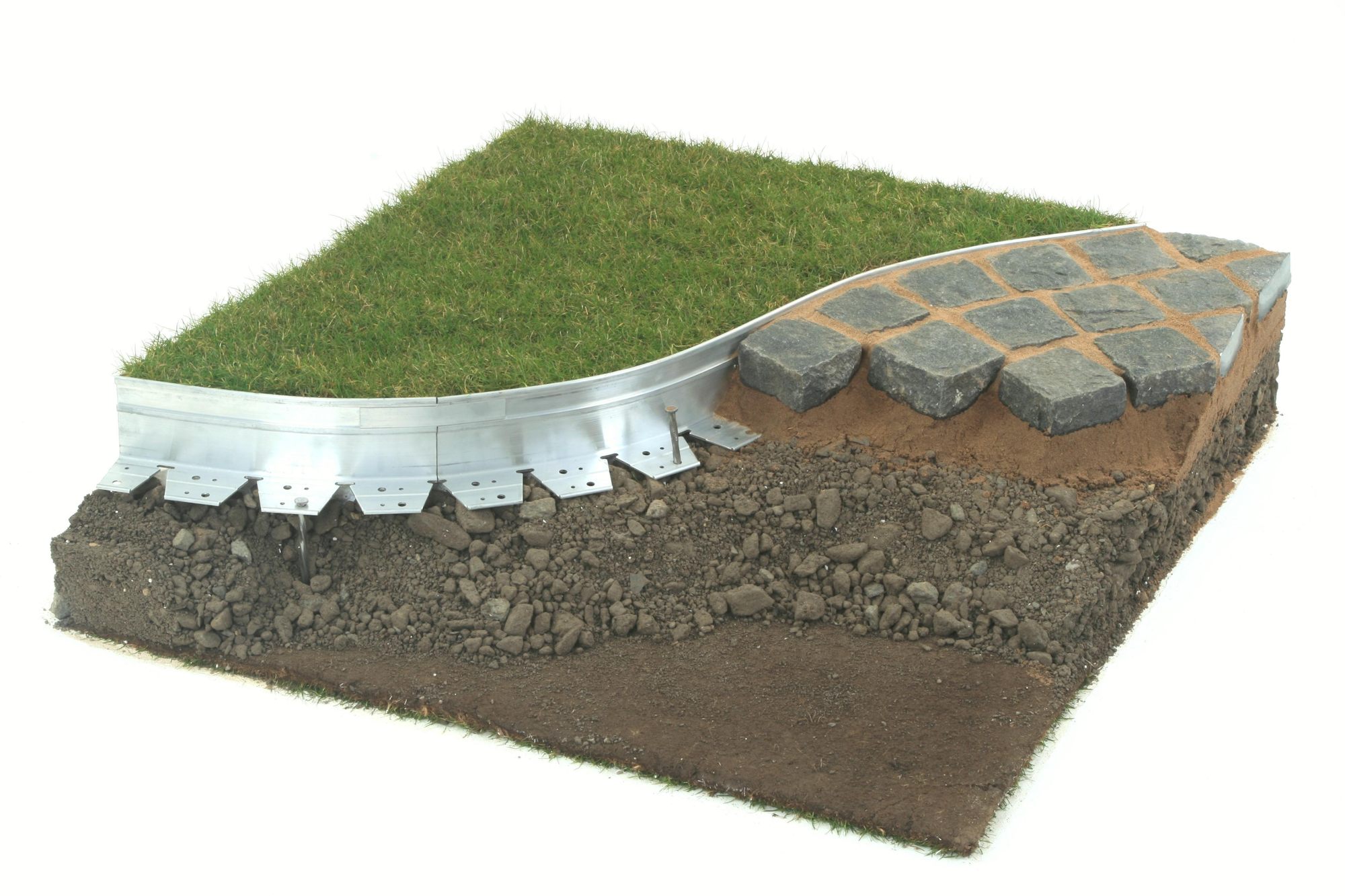

Metal driveway edging installs 4-5 times faster than concrete kerbing. It does not need a stable concrete base or haunching. This means you can start the next step in the installation right away.

Once you have installed the edging, metal stakes securely hold it in place and it is ready for backfilling and surfacing right away.

It is also considerably lighter than concrete. This means smaller vehicles can deliver it to the site, and workers can easily move it around the site as needed. One person can easily manage manual handling and laying.

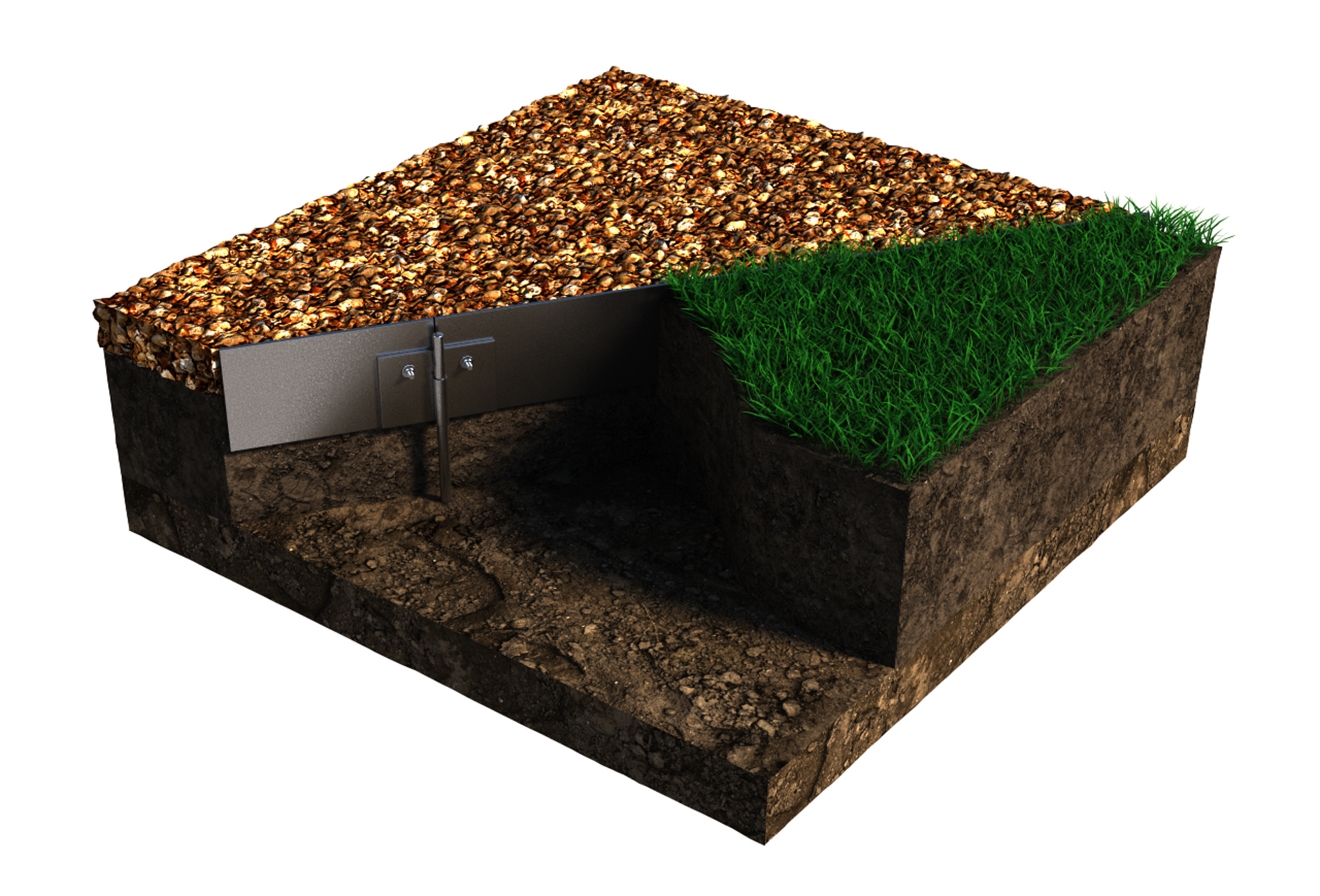

Steel and aluminium are the best materials for edging resin-bound driveways. They are less noticeable than concrete curbs. These materials let you place different colours next to each other with a nearly invisible border.

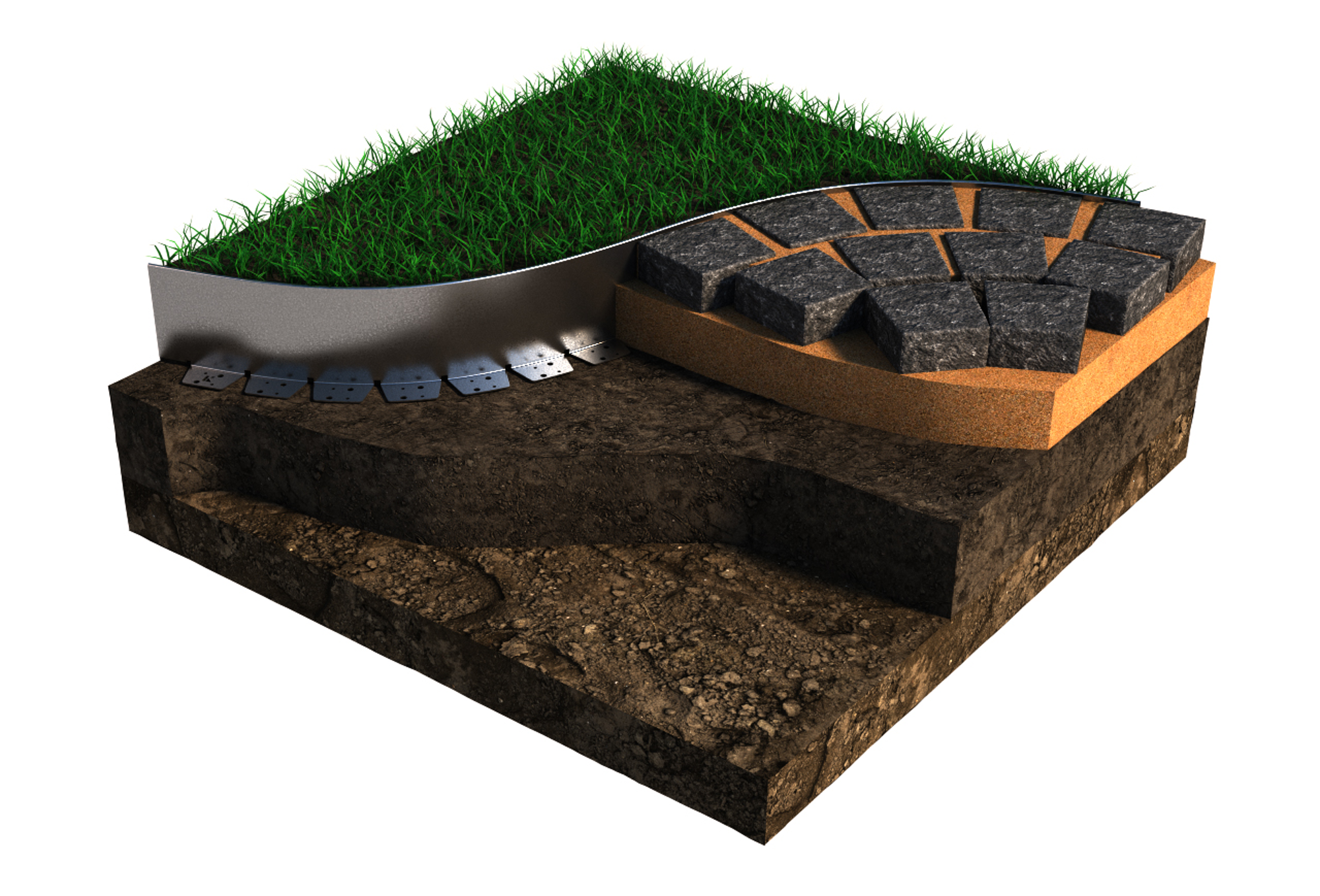

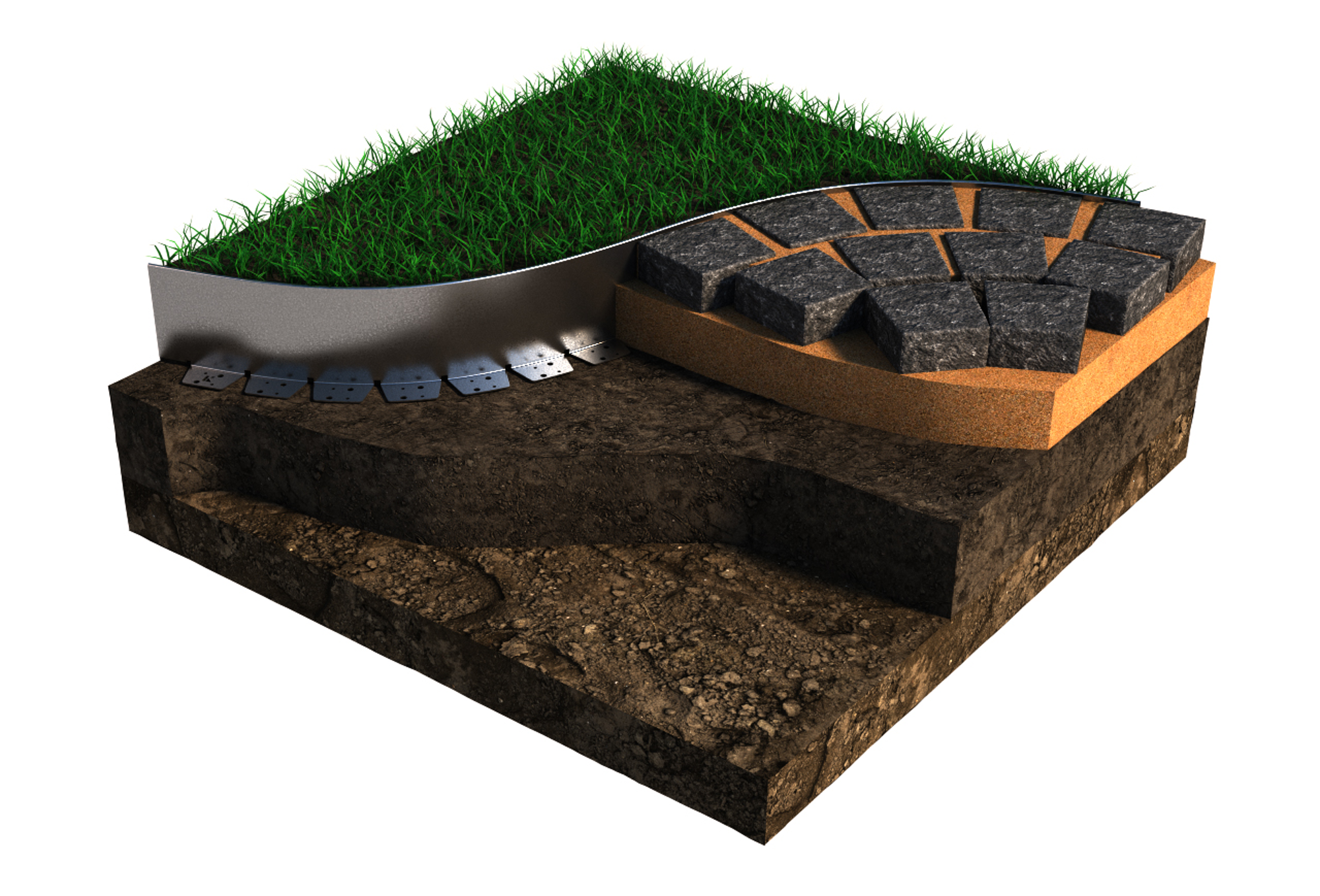

Heavy-duty Steel Kerb

The strength and durability of this premium quality heavy-duty steel kerb have made it a popular alternative to traditional concrete edging for civil engineering projects. Despite its rigidity, Bison can still be flexed to follow curves.

Supplied in a galvanised finish for corrosion resistance, Bison features a 7mm thick rolled top edge for safety and is manufactured in three heights (75mm, 100mm and 150mm).

Aluminium Landscape Edging

Suitable for lighter-duty flush fitting with surfaces such as asphalt, tarmac, rubber modified asphalt, resin-bound aggregate and block paving, AluExcel offers the added corrosion resistance of aluminium so this product is recommended for use in coastal areas.

AluExcel is manufactured in six thicknesses ranging from 5mm to 8.5mm and ten heights ranging from 15mm to 150mm and is supplied in a natural mill finish as standard.

Steel Landscape Edging

This steel edging is the perfect product for special driveways, as it offers a range of bespoke options. For a start, it is available in several finishes –galvanised or weathering steel (CorTen, or our more cost-effective alternative), or powder coated to any RAL colour.

Weathering steel is a particularly popular option due to the natural patina of oxidisation that forms on its surface over time. A natural barrier to corrosion, this also helps the product blend in with the earthy colours of mulch, soil and plants.

Urban can also be manufactured to bespoke heights and thicknesses and pre-formed during manufacture to create bespoke shapes for great visual effect or to accommodate landscaping and other features.

Opting for metal driveway edging presents various advantages, including:

Steel and aluminium stand out as the most commonly employed metals for driveway edging. Steel provides robustness and rigidity, making it suitable for heavy-duty applications or areas requiring enhanced stability. Aluminium, on the other hand, is lightweight, corrosion-resistant, and easy to handle.

Certainly, metal driveway edging is malleable and can be shaped to accommodate curved designs. Simply secure the edging in place and bend it according to the desired curvature.

When correctly installed, metal driveway edging is generally safe for pets and children. It is crucial to ensure that the edging is securely fixed and devoid of any sharp or exposed edges that could pose a risk of injury. Regular inspections and maintenance contribute to preventing potential hazards.

The lifespan of metal driveway edging varies based on factors such as material quality, environmental conditions, and maintenance practices. Under typical circumstances, it boasts a life expectancy exceeding 20 years.